Could it hurt to learn more about On-Shelf Availability (OSA) in retail and how to improve it? Hope you enjoy reading this article about on-shelf availability in today’s dynamic grocery store industry.

On-Shelf Availability (OSA) in Retail

Contrary to what you might think, online grocery shopping does not seem to be replacing the value of an in-store shopping experience. In fact, the Food Marketing Institute (FMI) reports that 42% of consumers say that they “like or love” to shop for groceries. Online shopping has increased since 2019, but according to FMI research, only six (6%) of consumers consider online as their primary channel for shopping. That said, two-thirds of shoppers report they do still occasionally shop online because they can find and purchase items with a few clicks and check stock availability... What if you could apply this same level of certainty and convenience in your retail store? How would higher shelf availability affect your business? We’ve got some great news from the field on the direct impact increasing OSA has on store performance just ahead. To set the table, so to speak, consider that On-shelf availability (OSA) is a primary focus for CPG and retail companies this year. The metric clearly indicates the percent of products available on store shelves when a customer is present and searching for those products.

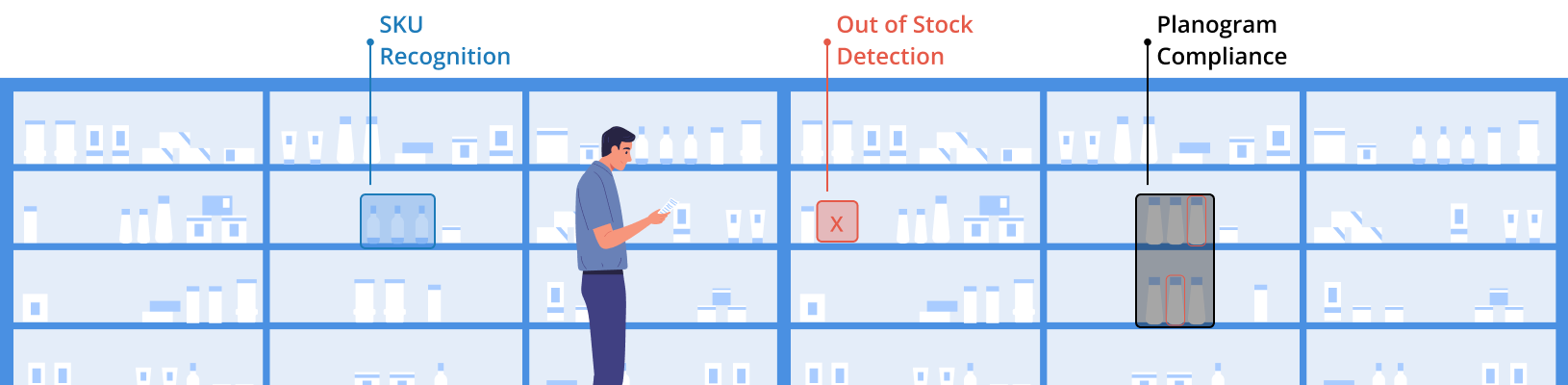

Preventing out-of-stock (OOS) problems in retail is crucial because it can cause losing loyal customers and a decrease in sales in the long term. To prevent this, retailers want to access reliable data quickly. However, old-school audit techniques cause the staff to waste limited time and make mistakes during data analysis. In this regard, the on-shelf availability of retail services has vital importance. However, traditional OSA retail service methods are not substitutes for modern technological solutions to obtain real-time views and data of rack space. Top retailers looking for ways to increase their sales have started to adopt these cutting-edge solutions to diagnose and fix shelf and supply issues.

The Hidden Importance of On-Shelf Availability

Inventory distortion. --the total financial damage caused by the decline in sales due to overstocking or out-of-stock situations – is clearly a huge problem for retailers. In both cases, retailers lose a lot of money. According to a study conducted by global research and consultancy firm, IHL Group, 10.3% of total retail sales in 2020 were lost to inventory distortion. That’s a top-line loss of $1.8 trillion, of which, 1.14 trillion USD was due to out of stocks, and $626 billion was due to overstock.

You may be tempted to think that these alarming results can be attributed to bad planning and inflexible logistics processes; however, that is not exactly correct. Two fundamental elements affecting this stunning financial loss include global responses to Covid-19, which retailers couldn’t control or change, and, interestingly, unavoidable data errors stemming from outdated, somewhat automated but still highly manual, store audit processes. Today, technological solutions to pinpoint store performance and update OSA scores are enabled to request regular (a.k.a. ‘real-time) shelf checks by category or wherever shelf-level trouble spots emerge. For more detailed information about these field-proven solutions, you can visit our website and discover mobile, fixed format or hybrid solutions like our Storesense and Shelfsight offerings.

Why On-Shelf Availability Suffers and Current Methods Fail?

OSA retail service has several problems:

• Customers buy it if they see it. So, if a product is not on the shelf, customers probably think it is out of stock. However, retailers have recovered from the technology debt related to replenishment timing but there’s still a gap between on-site and on-shelf. Meaning, that a retail inventory system, perpetual or not, only reports on stock status and not on whether products are on the shelf – or staged for replenishment from another location in-store. This tiny miscalculation becomes a problem for both parties because retailers cannot, humanly, watch the shelves in real-time to solve this issue in a timely fashion. Other real contributors to this problem include incorrectly placed products and tagging errors.

• Retailers should know when their business has the highest and lowest sales rate and schedule auditing, execution, and stock plans according to these surges in store-level customer demand. Failing, due to lack of automation, can cause inadequate (empty) or over-crowded replenishment of stock. Both of these situations result in loss of sales and loyal customers (the most ironic being that ‘over-crowding’ implies a product is a slow mover and, so, undesirable for some reason).

• Retailers make sophisticated weekly, monthly, and annual plans by forecasting consumer trends, stock status, and other inputs obtained from regular audits. So, customer satisfaction and sales rates depend on the degree to which these plans are adhered to. Poor execution and lack of timely communication between manufacturers and merchants can lead to stock problems. Unfortunately, an all-too-common situation involves retailers that fail to adequately factor in out-of-stocks (actually out-of-shelf) into a demand forecast and to operationally comply with their merchandising plan. The results are sub-optimal performance like insufficient supply for in-store demand and the resulting financial losses...

Current methods

• Manual audits are old-school methods that waste staff time and opportunities to engage with customers. Retailers rely on manual audits simply because they have been doing them for years and it’s what they know. Granted, manual audits are a reliable way to audit, but at the same time, they are not cost-efficient, and are complex compared to cutting-edge technological solutions which eliminate traditional human error.

• Perpetual Inventory Systems enable real-time sales tracking and may interpret "zero sales" as "out of stock”, or worse, ‘'zero demand'’ However, their lack of on-shelf precision is a problem. Research indicates that up to thirty-two (32%) to forty-five (45%) percent inaccuracy is possible.

• These OOS (out-of-stock) rates are calculated based on previous sales trends using POS data, which may or may not be accurate for slow-moving SKUs. Although nearly as efficient as manual audits, it still suffers from a low rate of real-time accuracy. Additionally, POS data is typically available at an aggregated level for partner brands rather than at the store level, preventing trade marketing teams from gaining detailed insights.

How to Improve Shelf Availability?

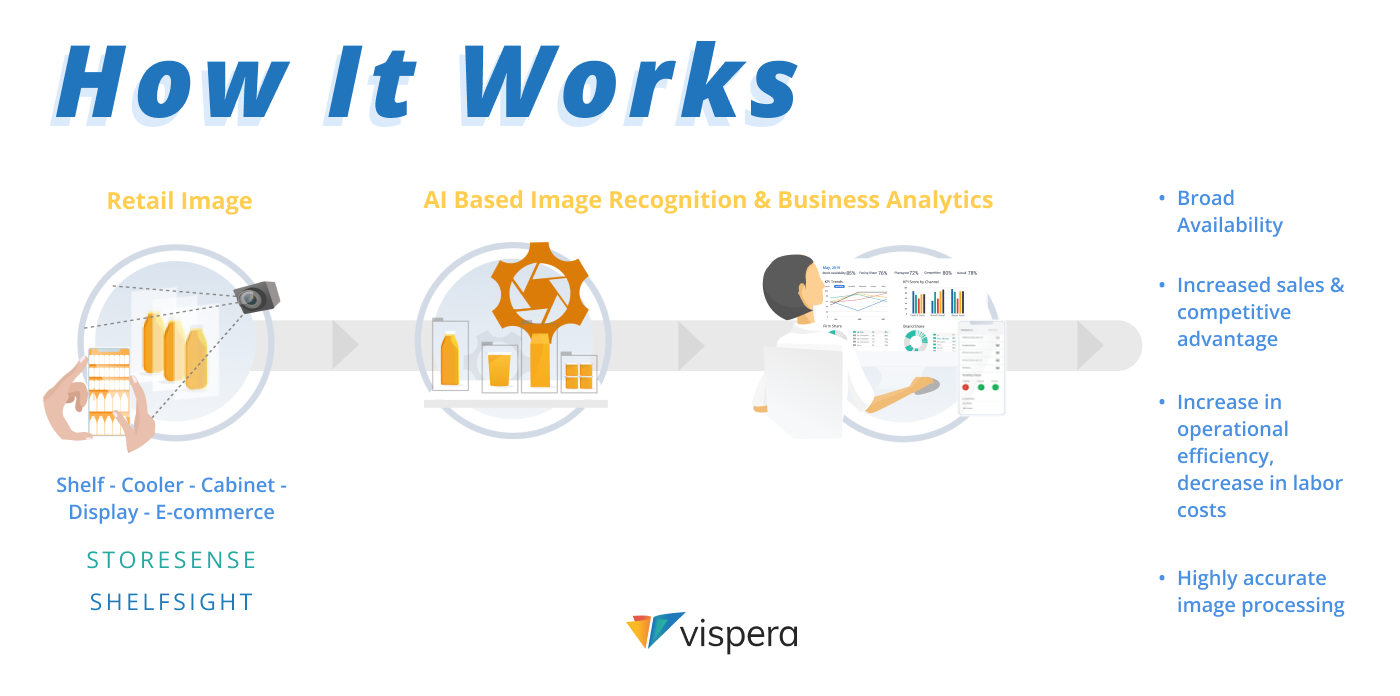

Rapidly evolving digital innovations in eCommerce over the past few years has altered retail sector dynamics and customer expectations. Retailers that haven’t kept up with this digital transformation are failing to give their customers the now expected optimal shopping experience. Understandably, retailers who adopted technological solutions to digitize their physical stores increased customer satisfaction and revenues. Vispera offers a way to digitize store shelves with image recognition (IR) and artificial intelligence (AI) to help retailers meet customer expectations post-COVID.

Our patented Image recognition solutions drive better store execution by gleaning big data from physical shelves and by eliminating outdated and time-consuming manual data collection and reporting processes. Vispera offers its' customers two unique image recognition solutions:

1. Storesense helps objectively evaluate teams with automated, mobile format performance metrics and tracking of shelf ‘health’ status.

2. Shelfsight is a real-time shelf monitoring and management system which digitizes store fixtures and their contents in real-time to eliminate out-of-stocks and enable quick replenishment by communicating with store-level staff about OOS and other deviations or anomalies.

By adopting these digital solutions, you can improve shelf availability. Visit our website now and request a pilot.